I think it's about time for you to meet some of my coworkers. I'll do this in installments so it's not too overwhelming. I'll call this first section Chicks and Dicks.

There's one other female welder in the shop. She's about my age, very friendly, and her name is Rhonda. Her name is going to take a while to stop making me twitch, because it's the punchline of a very bad, very sexual visual joke I learned a few years ago. Anywho, she's a nice girl, and I know next to nothing about her because we haven't really talked aside from the daily, "good morning."

The three other women I see on a regular basis are Linda, Jennifer, and Kim. Linda is the Human Resources lady, so she's in charge of pestering people to get their insurance/401(k)/payroll paperwork filled out in a timely fashion. Jennifer is another office employee, and she has some sort of connection to timekeeping. Kim... well, I'm not entirely sure what she does, but she sure does it in a chipper and perky way. She's the lone Pomeranian in this shop full of hound dogs, and we all kind of look at her and wonder where she gets the energy to be so happy all the time.

Now for the Dicks, or rather, the Richards. There are three of them. One works in another part of the shop, so I don't interact with him. The other two have been working closely with me this week, one as sort of a supervisor (I call him Rick), and one as an assistant (I call him Little Ricky). They're both really nice guys, eager to help and teach. Rick is an old-timer, Little Ricky just turned 21, and yet they get along really well, both with each other and everyone else.

More to come!

09 October 2008

Chicks and Dicks

Posted at

17:48

1 comments

![]()

07 October 2008

First And Second

First day? Kinda boring. Paperwork, safety instruction, and then hours and hours of test plates that refused to behave the way I wanted them to.

Second day? Awesome. I ran a few test plates which consistently came out nicely, and then spent the rest of the day building shelves out of square tubing. My back is killing me, but I'm very satisfied with my work.

Oh, and I got a barcode today! The time clock uses a barcode scanner, and my shiny, laminated, code tag was handed to me shortly after I arrived this morning. I feel official now.

So far, the biggest difference between AMK and Finebar is that the guys here actually work, and enjoy what they do. Nobody has complained about anything aside from the fact that work is really slow right now because of the economic situation. When the guys are complaining that they have to sit around and do nothing and getting paid for it, you know you work in a good shop.

Posted at

19:53

0

comments

![]()

30 September 2008

Almost There

My "first day" was actually five minutes of paperwork and the command to pee in a cup and then wait a week for the results of both the drug test and the background check before they'll give me a start date. Exciting, eh?

Another week of waiting is frustrating, but they'll be paying me more than they said they would, so I can deal with the delay. Maybe I can finally get my room clean in the meantime.

Posted at

10:32

1 comments

![]()

28 September 2008

Renaissance

Sorry for the delay there, folks. I'm finally back in the saddle, or at least tacking up. I start my new job on Monday! I'll be a TIG welder at a company that primarily makes and repairs aircraft parts. So, lots of stainless, aluminum, and titanium (that one will be new for me), and they're hiring me as a trainee, which means I'll be under a little less pressure to amaze them right off the bat.

I had my interview and test on Monday. The interview went well, with the bosses' two main concerns being my short time in the field and the fact that I'm female. Their last female welder, it seems, encouraged the attention of all the guys, and was asked to leave because nobody was getting any work done. I think I made it pretty clear that I had no problem fending off advances and telling the guys to get back to work, and the manager seemed satisfied.

The test was just to see where my skill level was, and while I'd spent some time at school last week practicing, I still wasn't where I wanted to be. I had to do butt joints on thin (18g) and thick (10g) stainless, and a T-joint of thin to thick. My thin butt was too hot, my thick butt was too cold, and my T, while a little too hot, was actually pretty nice.

So yeah, regular blogging will recommence, and hopefully y'all won't be bored to tears.

Posted at

00:14

0

comments

![]()

05 February 2008

The Sound of Silence

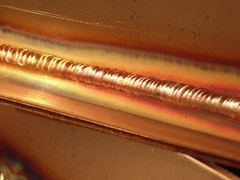

I'm taking some time off to get my surroundings sorted out and my head in the right place, but I will be looking for work soon. In the meantime, here are some pics of the TIG work I was doing in school last year.

The first two are stainless, the last is mild steel. I miss school.

Posted at

19:52

1 comments

![]()

03 January 2008

Instruction

Graduation is tomorrow, and even though I'm not going to the ceremony, I've been looking back over the last 15 months, thinking about the things I loved and hated about going to Baran. At the top of both the Love and Hate lists: teachers.

I had nine teachers, total. Of those, I love and respect two, I hate one, and like (to varying degrees) the other six. Let's start with the worst.

He's a pompous windbag. He thinks he's funny. He spends as little time welding as possible. He gives the same advice for every welding question: turn up the heat and go faster. He doesn't take refusal seriously, which is why he's the only teacher I ever seriously threatened to hit. (Yes, my braid nearly reaches my waist. Yes, you dated a girl who didn't mind you pulling on her braid. I, however, do mind. No, really. Stop it. I'm not kidding. Seriously. Piss off!) His teaching skills in the classroom are as bad as in the shop. He presents information exactly as we see it in the book, and can't take any other approach. He may be a good welder with lots of experience, but he's not a good teacher.

The teachers I like all have their good and bad qualities. There's the one with more certifications than you can shake an electrode at, who's a wizard at pipe welding, but if you make eye contact with him, he'll launch into a series of stories about near-death experiences he's had on the job over the last forty years. There's the one who gave me a ton of help when I was doing stick welding, but sneered about TIG welding, saying he could do just as well with a soldering gun. There's the ex-Marine who seems to enjoy his job, but has a very traditional approach to math class: if you can't learn it, just memorize it for the test. There's the guy who treats everything like a joke, and is rarely seen without an impish grin on his face, but surprised me when he gave me a demonstration that really helped my pipe welding technique.

The two teachers I love are the reason I'll be going back to visit from time to time. Don and Chris geniunely care about the students' understanding of theory and constantly push us to do better work in the shop. They give praise when it's due, temper their criticism with advice, and appreciate the fact that we've paid a lot of money to learn a trade from them. I rarely see either of them standing around doing nothing. They're always walking around, checking on our progress. They're friendly, helpful, intelligent, caring men, and I will miss both of them.

Monday and Tuesday will be my last days at Baran. Now I need to find a new job and save up enough money to start paying back my student loans. Welcome to the real world... have some debt.

Posted at

03:11

2

comments

![]()

16 December 2007

Distraction

At school (which I'll be done with in a few weeks, thank gods), we do a lot of bend tests. We weld two pieces of metal together, edge-to-edge, cut the newly-created piece into strips ("coupons") perpendicular to the weld, and bend them with a pneumatic hammer. This tests the strength of the weld. The guys at school are always amazed at how nice my coupons look, so I decided to write a little tutorial. The pictures here are of my 6G-downhand stick pipe test, and every single piece broke because I didn't bother cleaning out the slag.

How to Make Your Bend Tests Pretty

This is what a coupon looks like right after I (don't give a sh*t about doing a good job and) cut it. Not pretty.

The face was ground before cutting (easier for me to mark out the coupon that way), so now the root side needs to be ground. Always grind along the length of the weld so the grind marks end up perpendicular to the weld. Don't go crazy... once the root buildup is flush, you're just getting the mill scale off, and that doesn't require much pressure.

Now come the edges. First, grind along the length. Use the soapstone cutting lines on the face as a grinding guide.

This may look flat, but it isn't. How do you make it flat? Come around to the side (looking at the face of the coupon as it's clamped), hold the grinder so the wheel is parallel to the floor, and grind back and forth along the length of the coupon. Because the new grind marks are perpendicular to the first lot, it's easy to see where your high and low points are. The little batches of stripes here are the low points:

If the highs are especially high or the lows especially low, go back to grinding along the length of the weld, just in the high spots. Come around to the side for a few sideways-grinding passes now and then until it's pretty close to being flat. Use the sideways-grinding to finish, and the piece should look like this:

Put a small bevel on the corners, file off the burrs, and go break it!

Posted at

14:58

0

comments

![]()